QatarEnergy LNG Control Room Auxiliary Console – Engineering a New Standard in Mockup Excellence

- WEIMIAO MFG

- Aug 9, 2025

- 4 min read

Updated: Jan 19

Executive Summary In early 2025, Weimiao Control Panels completed the mockup stage of a custom-designed Auxiliary Console for LNG control room applications for QatarEnergy, one of the world’s largest LNG producers.. As one of the world’s largest LNG producers, QatarEnergy demands the highest standards of safety, ergonomics, and operational reliability. This 30-day mockup build showcased Weimiao’s engineering precision, adherence to strict international standards, and meticulous attention to detail. The inspection-ready console reflects the operational requirements of a 24/7 LNG facility, integrating advanced control features with ergonomic design for seamless operator performance. This milestone underscores Weimiao Control Panels’ manufacturing and engineering capability to deliver tailored control room solutions that meet critical industry demands.

Project Background – QatarEnergy and the Global LNG Landscape

QatarEnergy: Global LNG Scale & Market Position

QatarEnergy stands as one of the largest liquefied natural gas (LNG) producers in the world, with a strategic presence across global energy markets. Its production facilities in Ras Laffan Industrial City supply LNG to key regions in Asia, Europe, and beyond. This leadership is built on advanced infrastructure, long-term supply agreements, and a commitment to operational safety. With ambitious expansion plans to increase LNG output, QatarEnergy continues to set global benchmarks for efficiency, reliability, and environmental stewardship.

Why LNG Control Rooms Require Auxiliary Consoles

The LNG industry operates under demanding conditions, where precision, safety, and real-time responsiveness are critical. Control rooms serve as the nerve centers of LNG plants, managing complex processes that run continuously, 24 hours a day, 365 days a year. An Auxiliary Console supports the main control systems by:

Enabling Continuous 24/7 Operations: Providing operators with dedicated control interfaces to manage subsystems without interrupting primary DCS operations.

Facilitating Real-Time Monitoring and Emergency Control: Allowing rapid access to safety-critical functions, including emergency shutdowns and alarm management.

Integrating Seamlessly with the Main Distributed Control System (DCS): Ensuring data consistency, operational redundancy, and minimal downtime during maintenance or fault recovery.

Auxiliary Console Engineering Standards for LNG Control Rooms

Understanding the Client’s Requirements

Before a single component was sourced, Weimiao’s engineering team worked closely with QatarEnergy’s control room design specialists to fully understand the project requirements. This collaboration revealed four critical pain points:

Safety Compliance (IEC 61508 SIL2): The console needed to support reliable emergency shutdown functions with certified safety integrity levels to safeguard personnel and assets.

Electrical Safety & Wiring Regulations (NFPA 79): All internal wiring and electrical assemblies had to meet stringent safety standards to prevent hazards during operation and maintenance.

EMC Shielding & Grounding: Given the high-density electrical environment of an LNG facility, electromagnetic compatibility measures were essential to prevent signal interference and ensure stable control.

Ergonomic Standards (ISO 11064): Operators required a comfortable and efficient workspace for continuous 24/7 shifts, minimizing fatigue and maximizing response time during critical events.

Weimiao’s Solutions:

To address these challenges, Weimiao implemented a systematic engineering workflow: URS → SDS → FAT (mockup). This ensured that every stage—from defining the User Requirement Specification (URS), to producing the System Design Specification (SDS), to conducting the Factory Acceptance Test—was aligned with client expectations.

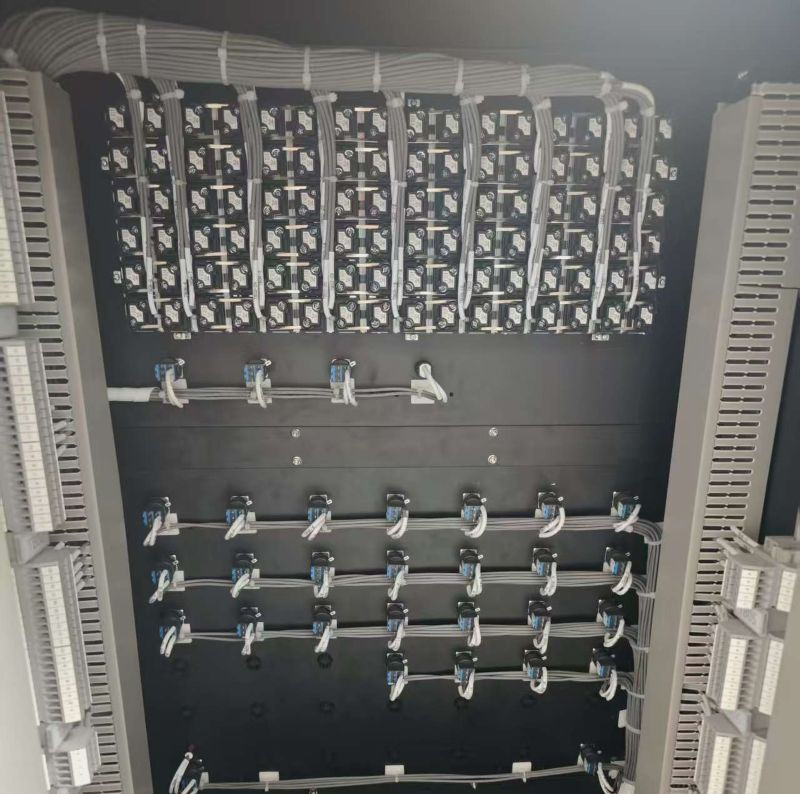

Precision Cable Routing & Component Placement: Wiring paths were optimized to reduce clutter, improve airflow, and facilitate easy inspection.

Advanced Shielding Methods: EMC clamps and shielded cable terminations were integrated to eliminate cross-talk and electromagnetic interference.

Integration-Ready Design: The mockup was built with a modular architecture, allowing straightforward scaling into bulk production without redesign.

Compliance Matrix & Engineering Standards

Weimiao’s design met or exceeded the following international standards:

IEC 61508 SIL2 Functional Safety: Ensuring that emergency shutdown (ESD) circuits perform reliably under all foreseeable conditions.

NFPA 79 Electrical Standard for Industrial Machinery: Guaranteeing safe electrical practices in industrial control equipment.

EMC Shielding & Earthing Practices: Implementing grounding layouts and shielding to maintain signal integrity and operational stability in high-interference zones.

Approved Component Brand List

To ensure reliability and maintainability, only approved global brands were used in the mockup:

Control & Signalling: IDEC – Emergency stop buttons, pilot lights, control relays

Termination & Wiring: Phoenix Contact – UT spring-cage terminals, EMC shield clamps

Power & Protection: Schneider Electric – Multi-9 miniature circuit breakers (MCBs), Acti9 power supplies

UPS & Transfer: Eaton – 9SX UPS series, Automatic Transfer Switch (ATS)

Technical Highlights

Redundant Profinet IRT Ring: Implemented with Phoenix Contact fibre patch panels for high-speed, fault-tolerant communication.

Hot-Swap Schneider I/O Modules: Designed for minimal downtime, allowing replacements without system shutdown during operational phases.

Front-Access Maintenance: All critical components can be reached from the front panel, simplifying inspection during FAT and reducing maintenance time.

ATS with <10 ms Transfer Time: The Eaton Automatic Transfer Switch ensures uninterrupted control in the event of power source changes.

Client Inspection & Mockup Approval

From concept to completion, the mockup build was executed within a 30-day timeline, reflecting Weimiao’s ability to mobilize engineering resources and meet tight schedules. Upon completion, QatarEnergy representatives conducted an on-site inspection, reviewing every aspect of the console’s design, wiring, and safety compliance. The inspection confirmed that the mockup met all specified design criteria, international safety standards, and ergonomic guidelines.With the mockup fully approved, the project is now positioned to transition smoothly into the bulk production phase, ensuring consistent quality across all future units.

Client Remarks & Anticipated Next Steps

During the inspection, QatarEnergy’s team provided positive feedback on the console’s build quality, ergonomic layout, and highly organized wiring system. The clean cable routing and accessible component placement were particularly praised for simplifying maintenance.Given the success of the mockup, there is strong potential to expand the project scope to cover multiple control rooms within QatarEnergy’s LNG operations as part of the full-scale production rollout.

Contact Weimiao – Custom Auxiliary Consoles for LNG, FPSO & Petrochemical Projects

Weimiao Control Panels specializes in designing and manufacturing custom auxiliary consoles for the most demanding industrial environments, including LNG plants, FPSOs, petrochemical facilities, offshore oil & gas platforms, and power generation projects.If you require a tailored control solution that combines engineering precision, safety compliance, and operational reliability, our team is ready to deliver.📩 Contact us today to discuss your project requirements and discover how Weimiao can support your next control room upgrade.

Comments