معرض المشروع

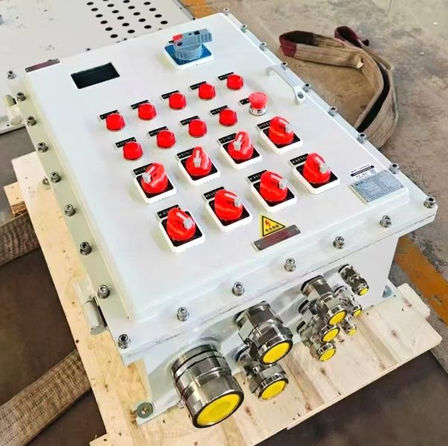

Custom ATEX Explosion-Proof Control Enclosure for Hazardous Zones

Project Overview – Tailored Flameproof Electrical Box for Oil, Gas, and Chemical Operations

This Weimiao project features a fully integrated explosion-proof enclosure designed for deployment in Zone 1/2 hazardous areas, specifically for control and protection of motors and field devices in oil, gas, and chemical processing sites.

The enclosure shown incorporates a combination of core electrical components, including:

CHNT thermal-magnetic circuit breaker

Meanwell industrial DIN-rail switching power supply

Compact transformer relay

High-durability terminal blocks with labeled circuit distribution

Industrial-grade wireless control receiver module

The enclosure is engineered using flameproof and sealed construction, built to contain internal ignition sources while supporting daily operations in flammable gas or vapor-rich areas.

Electrical Components and Functional Design

Operator-Safe, Certification-Ready Construction

Made from corrosion-resistant cast aluminum alloy, this flameproof housing is designed with:

Gas-tight gasketed doors

Pressure-resistant fasteners

Grounding points and antistatic grounding busbar

Internal mounting plate with structured component layout

Its compact form factor is suitable for wall-mounted or skid-integrated installation across FPSO platforms, wellheads, or chemical zone motor rooms.

Multi-Component Control Integration

This enclosure integrates key field-level automation and protection components:

Main circuit breaker for input control

24VDC power supply for logic systems or PLC sensors

Transformer relay for power conversion and overload response

Wireless receiver for handheld remote control or emergency shutdown operations

Terminal block array for multiple outgoing connections with individual labeling for maintenance ease

This design supports customized wiring schemes according to BOM or control system layouts, ensuring installation alignment and certification compliance.

Ideal for Use in Harsh, High-Risk Environments

Weimiao’s explosion-proof control boxes like this project are widely deployed in:

Oilfields – For motor starters, pump controls, or lighting circuits in areas with gas exposure

Gas regulating stations & LNG terminals – For remote valve activation and instrumentation interface

Chemical plants – Protecting sensitive relays, instrumentation, and automation hardware from corrosive gases and ignition risk

Mining & refinery operations – Where combustible dust or explosive atmospheres demand Ex-rated enclosures

Each unit meets or exceeds ATEX, IECEx, CNEX standards and can be configured for Ex d / Ex e / Ex de compliance depending on the application.

Weimiao – Trusted Partner for Certified Explosion-Proof Projects

At Weimiao, we specialize in the engineering and fabrication of custom ATEX-ready enclosures with full mechanical and electrical integration. Whether your needs involve:

A single terminal box for a remote pump skid

A multi-function control panel for a hazardous processing room

Or a fleet of field enclosures for a global energy infrastructure rollout

—we can support you from drawing review to production to certification.

We provide:

Pre-installed wiring, labels, and component layout

Drawings and datasheets for compliance audit submission

Batch production with export-ready packaging

Optional features: breather valves, internal lights, inspection windows, RFID tags

📩 Contact Weimiao today to discuss your flameproof enclosure needs—we’re ready to engineer your next ATEX-certified solution.